Browse

Dealer

Electric Lawnmower Motor

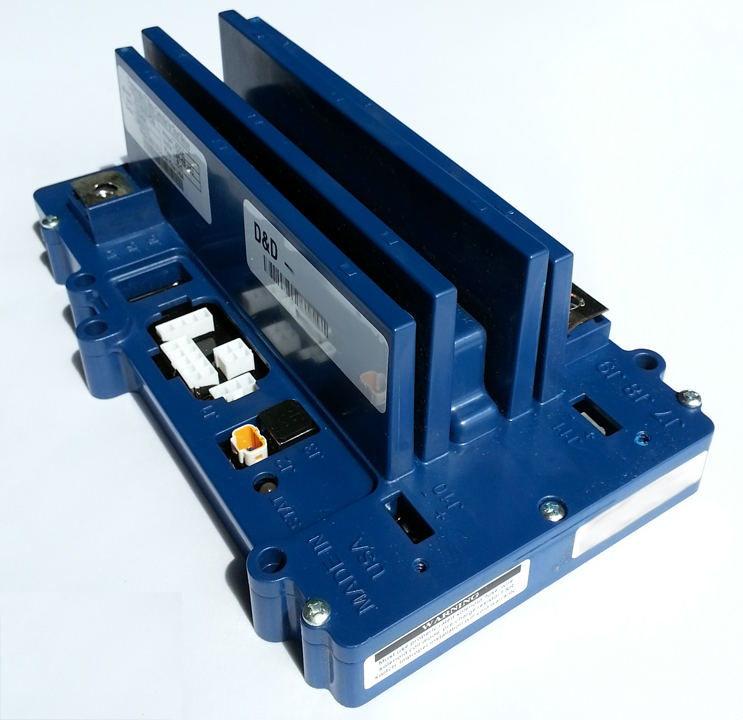

D&D Motor Systems is the premier electric lawn motor manufacturer in the U.S. for converting electric riding mowers. Our electric riding mower motors offer higher performance than the permanent magnet motors that are out there.

Our electric lawn motor has:

- Higher torque

- Better thermal capabilities

- Competitive Price

In addition, we offer a complete line of U.S. made electric riding lawn mower controllers to go with our electric riding mower motors.

Lower Performance - Push Mowers (Most Cost Efficient)

|

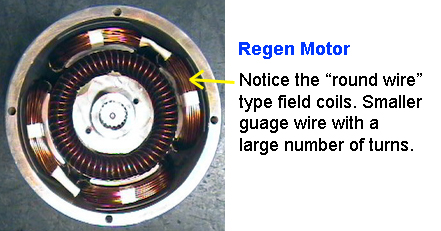

Part Number: 170-512-0003 (Regen)

Description: This is our smallest electric lawnmower motor, ideal for a DIY electric lawn mower or electric push mower conversion. As a Separately Excited (SEPEX) electric lawnmower motor, it requires a properly field-mapped electric lawnmower controller for optimal performance. For simpler electric lawn mower conversions or electric riding mower projects, we also offer basic series electric lawnmower motors compatible with PB6 pot box switches—perfect for DIY electric tractor or electric lawn tractor conversion builds. Let us know your setup, and we’ll help you choose the right components.

|

Push Mower Specifications

| Design Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Full Load Weight (lbs) | Voltage | Gear Ratio | Batteries/ Usable energy | Tire Size (Inches) | |||

| 70 | 24 | 8:1 | 2.2 kWh | 8 | |||

| 90 | 36 | 8:1 | 3.2 kWh | 8 | |||

| Motor Performance and Characteristics | ||||||

|---|---|---|---|---|---|---|

| PS | HP (Peak|Continuous) | Max Efficiency | Enclosure | |||

| 52 | 13.3 | 4.3 | 80.2 | Enclosed | |||

| 52 | 13.6 | 4.5 | 80 | Enclosed | |||

| Vehicle Performance | |||

|---|---|---|---|

| Top Speed (mph) | Contoller Amperage (Amps) | Acceleration | Range |

| 10 | 300 | Medium | 2-2.5 hrs |

| 10 | 300 | High | 3-4 hrs |

Other Available Motor Options: Low Performance Motor Options

Warning:

Returns are NOT accepted for these motors.

Warranty provided if system design

is approved by an engineer.

Medium Performance - Riding Lawn Mowers

|

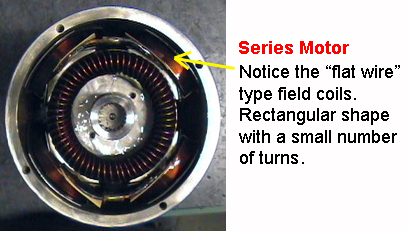

Part Number: ES-29 (Series)

Description: This electric lawnmower motor is ideal for electric riding mower conversions and DIY electric tractor projects. This motor is a simple series electric lawnmower motor design, which makes it compatible with most series electric lawnmower controllers, provided the throttle settings are properly programmed. A great choice for anyone building a DIY electric riding mower or planning an electric lawn tractor conversion.

|

Riding Lawn Mowers Specifications

| Design Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Full Load Weight (lbs) | Voltage | Gear Ratio | Batteries/ Usable energy | Tire Size (Inches) | |||

| 600 | 36 | 8:1 | 3.24 kWh | 10 | |||

| 900 | 48 | 8:1 | 4.32 kWh | 10 | |||

| Motor Performance and Characteristics | ||||||

|---|---|---|---|---|---|---|

| PS | HP (Peak|Continuous) | Max Efficiency | Enclosure | |||

| 1 | 9.9 | 3.8 | 80.5 | Ventilated | |||

| 1 | 9.5 | 3.8 | 80.5 | Ventilated | |||

| Vehicle Performance | |||

|---|---|---|---|

| Top Speed (mph) | Contoller Amperage (Amps) | Acceleration | Range |

| 11 | 400 | Medium | 1.3-2.0 hrs |

| 11 | 400 | Medium | 3.2-3.8 hrs |

Other Available Motor Options: Medium Performance Motor Options

Warning:

Returns are NOT accepted for these motors.

Warranty provided if system design

is approved by an engineer.

High Performance - Zero Turn Standing Mowers

|

Part Number: ES-116-6 (Series)

Description: This heavy-duty electric lawnmower motor is ideal for commercial-grade zero turn mower conversions and robust electric lawn mower conversion projects. As a series electric lawnmower motor, it's easy to pair with various electric lawnmower controllers without needing field mapping, making it a reliable choice for DIY electric riding mowers and electric lawn tractor conversions.

|

Zero Turn Standing Mowers Specifications

| Design Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Full Load Weight (lbs) | Voltage | Gear Ratio | Batteries/ Usable energy | Tire Size (Inches) | |||

| 1000 | 48 | 8 | 4.32 kWh | 15 | |||

| 1000 | 72 | 8 | 6.48 kWh | 15 | |||

| Motor Performance and Characteristics | ||||||

|---|---|---|---|---|---|---|

| PS | HP (Peak|Continuous) | Max Efficiency | Enclosure | |||

| 6 | 13.3 | 5.2 | 83.1 | Enclosed | |||

| 6 | 20.0 | 7.7 | 83.1 | Enclosed | |||

| Vehicle Performance | |||

|---|---|---|---|

| Top Speed (mph) | Contoller Amperage (Amps) | Acceleration | Range |

| 18 | 500 | Medium | 2.5-3.5 hrs |

| 23 | 500 | High | 4.0-4.5 hrs |

Other Available Motor Options: High Performance Motor Options

Warning:

Returns are NOT accepted for these motors.

Warranty provided if system design

is approved by an engineer.